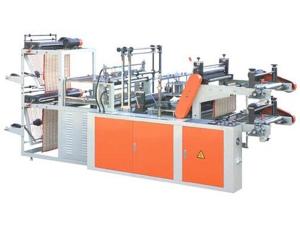

Plastic Bag Making Machine

Plastic Bag Line/ Bag Maker/ Plastic Bag Machine

Characteristics

1) The micro-computer control system is the perfect combination of electro mechanical technology and ultrasonic sealing technology.

2) Stepping motor (servo motor control system can be selected and equipped)

3) Arbitrary fixed length

4) Accurate and stable photocell tracking

5) Stops automatically if the label is lost

6) Automatic punching, automatic counting and counting alarm

7) Heat-sealing for decorative borders

8) Automatic constant temperature, perfect and smooth sealing, with EPC control

-

- Heat Sealing and Cool Cutting Plastic Bag Making Machine, XD-FQ600

This heat sealing plastic bag making machine is designed for the production of vest bags, flat bags, packing bags, etc. The machine uses a computer control system where you can preset your requirements and let the equipment operate at maximum efficiency, reducing waste and saving you money. The material is fed automatically and will shut down immediately when the roller is out of material.

-

- Fully Automatic Double Channel Plastic T-shirt Bag Making Machine, XD-PT800

The double channel plastic t-shirt bag making machine is suitable for the sealing and cutting of high-density polyethylene (HDPE), low-density polyethylene (LDPE) and polypropylene (PP) plastic film. This makes the equipment the preferred choice for producers of vest bags and flat bags.

-

- Double Channel Bottom Seal Plastic Die-Cut Bag Making Machine, XD-F450

The bottom seal plastic die-cut bag making machine is a high quality piece of equipment that is designed for sealing and cutting high-density polyethylene (HDPE), low-density polyethylene (LDPE) and polypropylene (PP) plastic film for the production of bags. The bag maker is used in lines to manufacture D-cut bags and flat bags.

-

- Heat Sealing and Heat Cutting Plastic Bag Making Machine, XD-RQ600

This machine is designed for thermal cutting and bag making utilizing films such as BOPP, OPP, PE, etc. And it is ideal equipment for making sock bags, towel bags, courier bags and ornament bags, etc.

-

- Plastic Book Cover Sealing and Cutting Machine, XD-S700

This plastic book cover sealing and cutting machine is utilized to manufacture PE (polyethylene) book covers. The sealer/cutter is designed to reduce labor costs, improve efficiency and maximize product quality.

-

- Double Channel Perforated Plastic Bag Making Machine, XD-VB600

The perforated plastic bag making machine is ideal for processing LDPE, HDPE plastics to produce blank bags, colored bags, flat bags and many other types of soft plastic packing bag items.

-

- PE/PP Film Zipper Bag Making Machine, XD-Z800A

This machine was independently developed and manufactured by our company. The worktable of the equipment is multifunctional and it is utilized to produce zippered bags of various sizes. The high performance and high quality bag maker is guaranteed to keep your production line running efficiently.

-

- Air Bubble Bag Making Machine, XD-BF800

This air bubble bag making machine is suitable for the production of protective packaging products. The machine is used for laminating pearl cotton and compound bubble film bags. These products are important for packaging electronics components such as TVs, computers, and toys in order to protect them during shipping and storage.

-

- Computerized Roll-to-Sheet Cutting Machine, XD-QZ1000

The computerized roll-to-sheet cutting machine is a compact unit that is highly automated and provides precise cutting for rolled materials, particularly for the production of plastic bags.

Production Process

1. Reel fabric feeding

2. EPC control (edge position control)

3. Center folding parts

4. Heat sealing for the bottom

5. Zipper attached and sealed

6. Automatic punching

7. Heat cutting/ Cold cutting

8. Send to sorting machine

Ruian Xinda Packing Machinery Co.,Ltd.

Hot line: +86-577-65162166

Fax: +86-577-65131220